In 1996, Mike Harris founded Sea Shutters after realizing that existing shutters being sold on the market cracked, pealed, and did not stand up to flying debris from gale-force winds. After experimenting with various materials, Harris found that protruded fiberglass was stronger than other materials, that it didn’t warp, and that the paint coating was superior to other products. Homes located near the beach get soaked by heavy rain, sea water, and high winds and traditional shutters required a lot of yearly maintenance. Harris began working closely with architects, who recommended Sea Shutters to their clients building new homes and condos. The close working relationship with the building designers and general contractors proved to be a successful marketing strategy.

Today, Sea Shutters is a successful family-run operation with six employees and all manufacturing processes and headquarters located in Marianna.

“We have a higher pay scale than most of the local jobs, which is important to add to the local community and our economy,” said Derek Preston, a son-in-law and the production manager for the company.

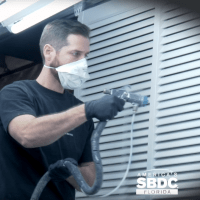

Sea Shutters’ production process uses modern CNC (Computer Numerically Controlled) equipment to cut the lovers to the correct length, while another CNC machine cuts the notches for the lovers in the side panels. After all pieces are cut, the sections are fastened together in a large clamp. The completed shutters are painted with high-quality paint and backed dry. The completed shutters are then shipped to the customer by truck.

Preston also handles most of the estimating, scheduling and marketing. In 2014, he contacted the Florida SBDC at the University of West Florida in Panama City seeking assistance with cash flow and marketing. Len Eichler, a business growth consultant, worked with Harris and Preston on marketing ideas and ways to streamline some of their production operations.

“Having someone with extensive experience to review our marketing plans was valuable,” Preston said. “It was especially helpful to have someone guide us on developing a new mobile ready website – I think this will really expand our customer base. Len has manufacturing experience, so he dug into our production process and highlighted areas that we could modify. This analysis has allowed us to get finished product out the door faster."